HOUSEHOLD &

INDUSTRIAL

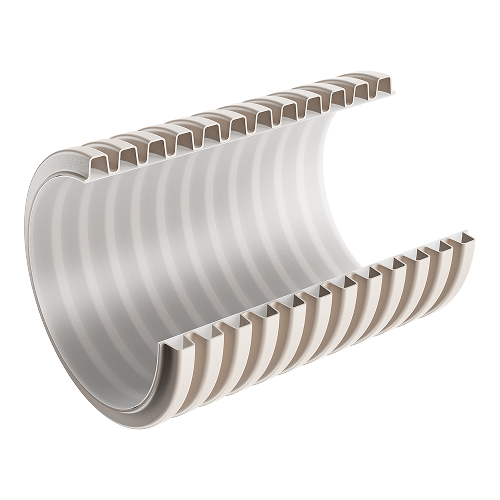

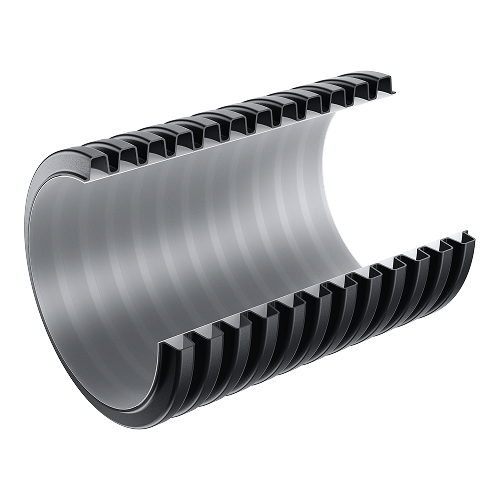

BUILDING VENTILATION PIPES

Central ventilation systems are essential in modern, highly insulated buildings, providing natural air exchange in airtight buildings. They improve air quality, prevent mould growth, and increase energy efficiency through heat recovery. Our high-quality ventilation pipes are at the heart of these systems, ensuring efficient air supply and exhaust. They provide a healthy and comfortable indoor environment while helping to save energy. We are a manufacturer of ventilation pipes that are essential for modern, energy efficient buildings.

Material: HDPE, virgin material

Inner layer: smooth

Antibacterial

Odor-neutral

Antistatic

Min. bending radius: 60 mm, horizontal and vertical

Ring stiffness: ≥ 8 kN/m²

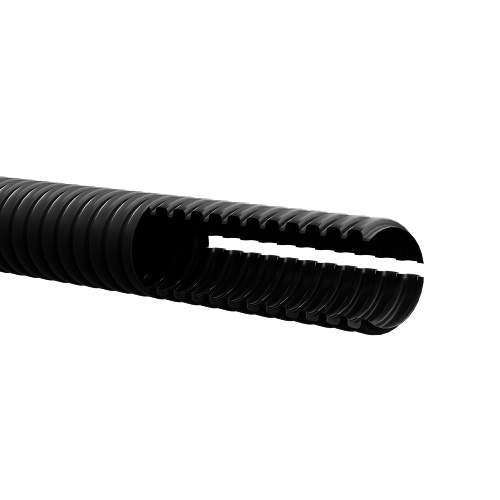

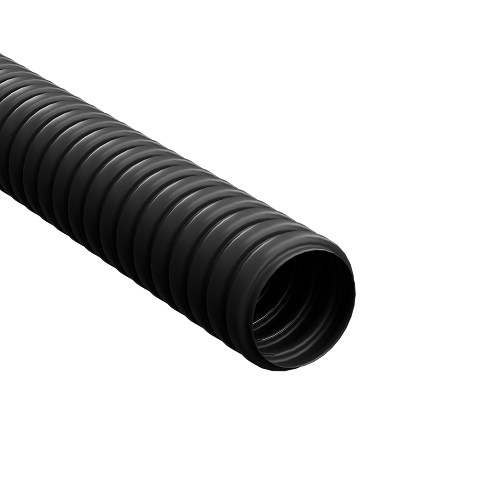

WIRING PROTECTION

Our cable protection provides comprehensive resistance to moisture, dust and abrasion. This significantly reduces the risk of signal interference and material damage to the cables.

Diameter from 4.5 mm to 37 mm

Material: PP (with or without regrind material) or PA6

Optional longitudinal slit

Temperature range: -40°C to +120°C

Flammability class: UL 94-V0 / US-FMVSS 302

Diameter from 4.5 mm to 37 mm

Optional longitudinal slit

Temperature range: -40°C to +120°C

Material: PP (with or without regrind material) or PA6

Flammability class: UL 94-V0 / US-FMVSS 302

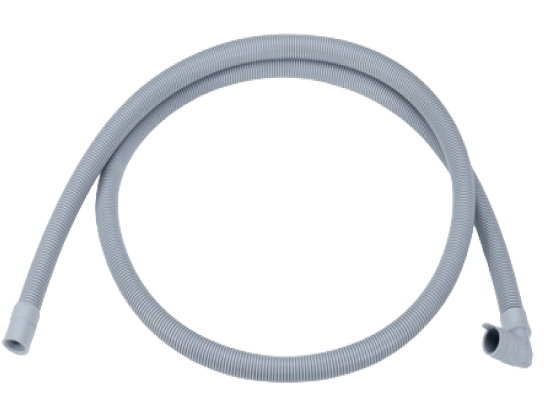

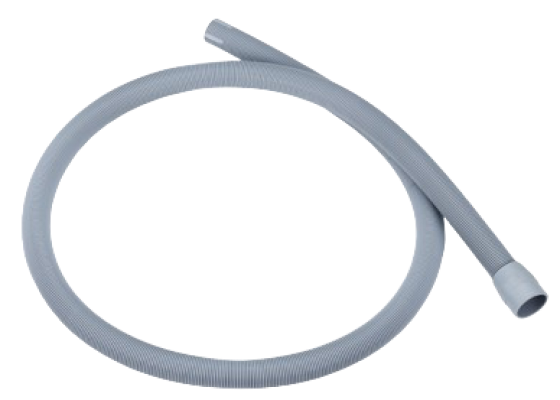

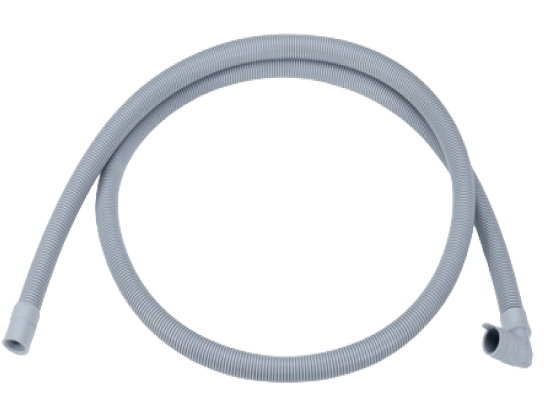

Inlet, Outlet and AquaStop Hose

The mechanism in the AquaStop hose automatically stops the water flow if a problem is detected.

The water is then used inside the machine for the cleaning process. It is mixed with the cleaning agent to effectively clean the dirty items. After the washing or rinsing process, the now dirty water must be drained from the machine. This is where the drain hose comes into play, directing the wastewater from the machine into the household drain.

Both hoses, the inlet and the outlet hose must have certain characteristics. They should be flexible for ease of installation and to allow adaptation to different environments. In addition, resistance to cleaning chemicals is important, as these hoses regularly come into contact with various washing and cleaning agents. A long lifespan is also important in the hoses to ensure the reliability and safety of the household appliances.

The water is supplied to the machine from the domestic water supply via an inlet hose (which can also be an AquaStop hose)

After the cleaning process, the dirty water is directed to the household drain through the outlet hose

Both hoses need to be flexible for ease of installation and to enable adaptation

Resistance to cleaning chemicals is important

A long lifespan is essential to ensure the reliability and safety of the machine

Overmoulding with PTV or TPV at the ends

Diameter between 4.5 mm and 160 mm

Standard material: PP

For the Aquastop system, we are a supplier of the hoses

Resistance to cleaning chemicals is important

Overmoulding with TPE or PTV at the ends

Diameter between 4.5 mm and 160 mm

A long lifespan is essential to ensure the reliability and safety of the machine

After the cleaning process, the dirty water is directed to the household drain through the outlet hose

The water is supplied to the machine from the domestic water supply via an inlet hose (which can also be an AquaStop hose)

Standard material: PP

Both hoses need to be flexible for ease of installation and to enable adaptation

For the Aquastop system, we are a supplier of the hoses

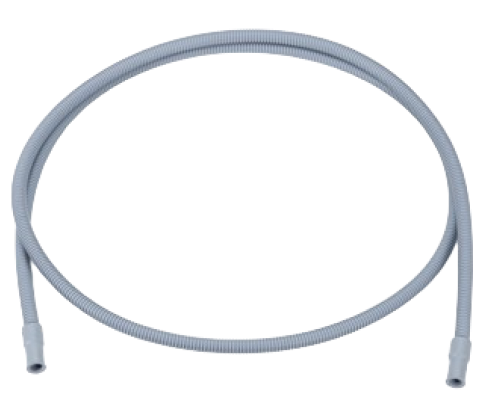

Vacuum Hose

Another important aspect in the design of the vacuum hose is the optimisation of its acoustic properties. A well-constructed hose can help reduce the noise level of the vacuum cleaner during operation. This increases user comfort, as a quieter vacuum cleaner is perceived as more pleasant and reduces noise pollution in the usage environment.

Moreover, it is important that the vacuum hose is highly flexible. This allows for simple handling and an ability to easily access various areas when vacuuming. Flexibility also means that the hose can be easily bent in different directions without kinking or becoming damaged, which could impair the suction efficiency. The durability of the vacuum hose is another crucial factor. A high-quality and long-lasting hose must withstand daily stresses without tearing or wearing out. This ensures that the vacuum cleaner can be used effectively over a longer period without the need to replace the hose. This increases both the reliability and the economy of the appliance.

Airflow optimisation to reduce air resistance and energy consumption

Ecological and economic benefits due to energy efficiency

Acoustic optimisation for reduced noise and enhanced comfort

High flexibility in the hose facilitates handling and accessibility

Flexibility prevents kinking and damage and ensures efficiency

Durability of the hose is important with regard to the longevity and reliability of the appliance

Diameter between 4.5 mm and 160 mm

Standard material: EVA and LDPE

Conductive or non-conductive

Airflow optimisation to reduce air resistance and energy consumption

Diameter between 4.5 mm and 160 mm

Acoustic optimisation for reduced noise and enhanced comfort

Conductive or non-conductive

Standard material: EVA and LDPE

Ecological and economic benefits due to energy efficiency

Flexibility prevents kinking and damage and ensures efficiency

Durability of the hose is important with regard to the longevity and reliability of the appliance

High flexibility in the hose facilitates handling and accessibility

Safety Cap

The safety cap on the pressure tank of the steam cleaner effectively protects the user against such injuries by preventing the tank from being opened under dangerous conditions. This ingenious mechanism makes a significant contribution to user safety

Adjustable opening pressure

Consists of 12 individual parts

Adjustable emergency opening pressure

Adjustable opening pressure

Consists of 12 individual parts

Adjustable emergency opening pressure