AUTOMOTIVE ICE

PRODUCTS

COOLANT CAP

Caps for cars, lorries, vans, agricultural and construction machinery

Annual production volume: 35 million units

Decades of experience and continuous development

Single-stage or two-stage valve function

Optionally available as a safety lock – will not open in case of excess pressure

Printing according to customer specification

Various opening pressures available according to specific customer requirements

Caps for cars, lorries, vans, agricultural and construction machinery

Printing according to customer specification

Annual production volume: 35 million units

Various opening pressures available according to specific customer requirements

Single-stage or two-stage valve function

Decades of experience and continuous development

Optionally available as a safety lock – will not open in case of excess pressure

COOLANT CAP

Tank filler caps

Compatible with all standardised and commercially available interfaces

A variety of diameter sizes

Ventilated and non-ventilated tank filler caps

Locking and non-locking mechanism

For blow-moulded or rotation-moulded plastic tanks

Ergonomic shape, design and feel

Up to a tightness of 0.5 bar depending on customer requirements

For metal tanks in stainless steel or aluminium

Tank filler caps

Locking and non-locking mechanism

A variety of diameter sizes

Compatible with all standardised and commercially available interfaces

Up to a tightness of 0.5 bar depending on customer requirements

Ventilated and non-ventilated tank filler caps

Ergonomic shape, design and feel

For metal tanks in stainless steel or aluminium

For blow-moulded or rotation-moulded plastic tanks

Oil filler caps

Oil filler caps for cars, lorries, vans, agricultural and construction machinery

Compatible with all standardised and commercially available interfaces: bayonet and threaded necks available

Annual production volume: 8 million units

Decades of experience and continuous development

Coloured symbols and lettering available upon request

Compact and simple construction

Oil filler caps for cars, lorries, vans, agricultural and construction machinery

Annual production volume: 8 million units

Decades of experience and continuous development

Coloured symbols and lettering available upon request

Compact and simple construction

Compatible with all standardised and commercially available interfaces: bayonet and threaded necks available

Oil filler caps

SCR Systems

Safe filling of the AdBlue tank thanks to the integrated magnetic insert in the filler neck

A variety of cap versions: 40 mm and 60 mm, choice of locking or non-locking mechanism with special AdBlue®-resistant locking cylinders

Design and manufacture of system solutions – from caps to filler necks, including all components and the lines, right through to tanks

A range of opening pressures or membrane-controlled ventilation

Various system solutions for AdBlue® tanks in blow-moulded or rotation-moulded versions: flanged-mounted (screwed), screwed with thread on filler neck (permanent catch mechanism), welded (plastic on plastic), with or without retaining fitting

Coloured symbols and lettering available upon request

AdBlue® resistance on account of plastic filler necks and special locking cylinders

SCR Systems

A range of opening pressures or membrane-controlled ventilation

Design and manufacture of system solutions – from caps to filler necks, including all components and the lines, right through to tanks

Safe filling of the AdBlue tank thanks to the integrated magnetic insert in the filler neck

A variety of cap versions: 40 mm and 60 mm, choice of locking or non-locking mechanism with special AdBlue®-resistant locking cylinders

Various system solutions for AdBlue® tanks in blow-moulded or rotation-moulded versions: flanged-mounted (screwed), screwed with thread on filler neck (permanent catch mechanism), welded (plastic on plastic), with or without retaining fitting

Coloured symbols and lettering available upon request

AdBlue® resistance on account of plastic filler necks and special locking cylinders

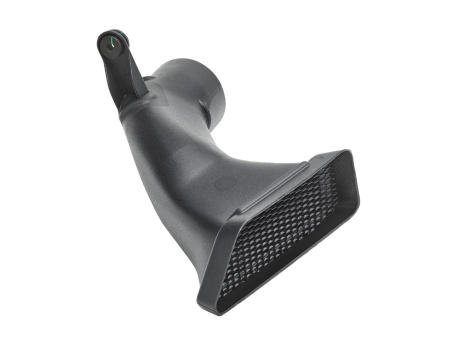

Air Filter Hoses

Raw Material: TPEV, TPEE

Technology: suction blow molding

Nipples welded by hot mirror technology.

Specific finishing station to perform pressure drop test.

Raw Material: TPEV, TPEE

Specific finishing station to perform pressure drop test.

Nipples welded by hot mirror technology.

Technology: suction blow molding

Air Filter Hoses

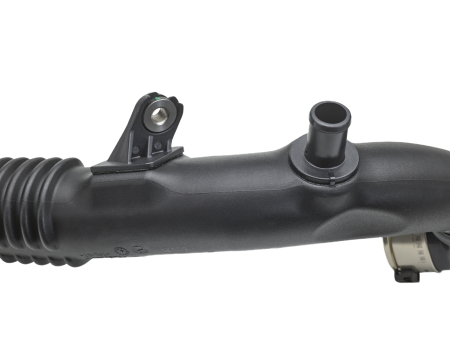

CAC HOSES

Raw Material: PA6GF15, PA66GF20

Technology: suction blow molding

Connectors assembly

Specific finishing station to perform pressure drop test

Fixing bracket welded by hot mirror technology

CAC HOSES

Connectors assembly

Technology: suction blow molding

Raw Material: PA6GF15, PA66GF20

Fixing bracket welded by hot mirror technology

Specific finishing station to perform pressure drop test