AUTOMOTIVE BEV PRODUCTS

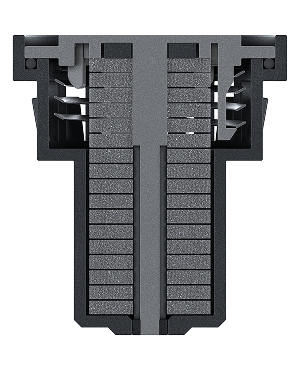

BATTERY VENT

The battery installation is a critical component within a Battery Vent (BEV). To ensure optimal performance and safety, a high-quality battery vent system is essential. Our product offers a streamlined design and a simple installation process, while maintaining reliable functionality throughout its lifetime.

IP67 & IP69K Ingress Protection

High flow rate capacity: More than 100 I/s at 300 mbar

High-performance material: Resistant to high temperature

Breathing function: . 1.4 I/min at 70 mbar

Membrane blockable for EOL tightness testing

Mounting with M6 screws ( Assembly torque: 7Nm)

Particle Filtration: > 0.8 mm (Optional)

UL94-V0 Conform materials

IP67 & IP69K Ingress Protection

High flow rate capacity: More than 100 I/s at 300 mbar

Mounting with M6 screws ( Assembly torque: 7Nm)

Breathing function: . 1.4 I/min at 70 mbar

Particle Filtration: > 0.8 mm (Optional)

High-performance material: Resistant to high temperature

Membrane blockable for EOL tightness testing

UL94-V0 Conform materials

BATTERY VENT

The battery installation is a critical component within a Battery Vent (BEV). To ensure optimal performance and safety, a high-quality battery vent system is essential. Our product offers a streamlined design and a simple installation process, while maintaining reliable functionality throughout its lifetime.

BREATHER

IP67 & IPX9K* ingress protection

Breathing function: 15-70 l/h at 70 mbar

Clip-in or threaded assembly

High quality material

Membrane: PTFE or PET (PFAS free)

UL94-V0 conform materials possible

Oil rating: 7 (Optional)

Sealing Material: Silicone / EPDM

BREATHER

IP67 & IPX9K* ingress protection

Breathing function: 15-70 l/h at 70 mbar

Membrane: PTFE or PET (PFAS free)

Clip-in or threaded assembly

High quality material

Oil rating: 7 (Optional)

UL94-V0 conform materials possible

Sealing Material: Silicone / EPDM

Drainage valves

This advanced valve ensures optimum performance under the most demanding conditions and is designed to provide robust protection. It manages potential coolant breaches, which is critical in preventing of potential thermal runaway scenarios.

Reutter designs drainage valves tailored to your specific needs. Whether it’s super-absorbent technology or electrically controlled systems, Reutter delivers innovative solutions that exceed expectations.

IP67 & IP69K ingress protecttion

Clip-in assembly

Opening detection by senser

Enhanced safety

Rapid coolant evacuation

High-performance material: Resistant to high temperature

High-performance plastics

UL94-V0 conform mterials

Drainage valves

BEV Coolant Cap

This enables the use of a more compact valve structure, as there is no need to accommodate high volumes of steam. Our BEV coolant caps are designed to meet these requirements, ensuring efficient operation and longevity.

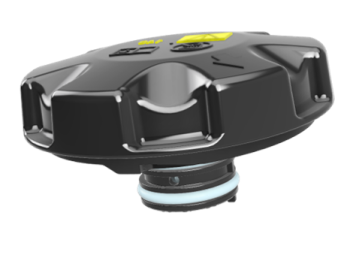

BEV COOLANT CAP

This enables the use of a more compact valve structure, as there is no need to accommodate high volumes of steam. Our BEV coolant caps are designed to meet these requirements, ensuring efficient operation and longevity.

Simple, robust and functional design

Adjustable pressures

Single-stage overpressure is sufficient

Connection to the interface may not have to be as “strong” – bayonet rather than full thread

Weight reduction (>50%)

Alternative materials

Downsized caps

Caps may be hidden and not freely accessible – marking could be reduced

One O-Ring as standard could be sufficient

Simplified marking

Implementation of standard geometry for filler necks with reduced use of filling guns

Simplified assembly

Better-fitting materials for the complete application e.g. >PP< where additives may not be needed

Weight reduction (>50%)

Simple, robust and functional design

Adjustable pressures

Alternative materials

Better-fitting materials for the complete application e.g. >PP< where additives may not be needed

Caps may be hidden and not freely accessible – marking could be reduced

Implementation of standard geometry for filler necks with reduced use of filling guns

Single-stage overpressure is sufficient

Simplified marking

Connection to the interface may not have to be as “strong” – bayonet rather than full thread

Simplified assembly

Downsized caps

One O-Ring as standard could be sufficient

Similar designs are already familiar and established in some OEM installations. It can be equipped with specific stop features (haptic feedback) and drainage channels above the small O-Ring.

COOLING TUBE

Conventional blow moulded

Suction blow moulded

Extruded (smooth /corrugated)

Thermo-formed

Quick connectors assembled

Tightness tests according to specification

All extrudable plastic grades can be processed

Design will be adapted to suit the customer environment

Connectors that are already established on the market can be implemented / used

Quick connectors assembled

Tightness tests according to specification

Connectors that are already established on the market can be implemented / used

All extrudable plastic grades can be processed

Design will be adapted to suit the customer environment

Conventional blow moulded

Suction blow moulded

Thermo-formed

Extruded (smooth /corrugated)

COOLING TUBE

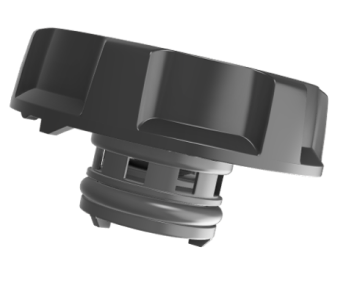

Immersion coolant cap

Specific working pressures

Can be adapted for custom designs

Ensures that coolant fluid remains contaminant-free

Immersion coolant cap

Specific working pressures

Ensures that coolant fluid remains contaminant-free

Can be adapted for custom designs

Ventilation Air Duct

Technology: standard blow-molding

Raw Material: HDPE

Integrated brackets

Specific dedicated machining station

Assembly of metallic clip or foams

Raw Material: HDPE

Integrated brackets

Assembly of metallic clip or foams

Technology: standard blow-molding

Specific dedicated machining station